When a well is constructed section by section, during any...

Well Barriers and well barrier elements are specifically designed layers of defense in a wellbore that prevent an uncontrolled release of formation fluids to a weaker / depleted sub-surface zone or the external environment. The former case is referred to as an ‘underground blowout’ and the latter case is referred to as a ‘blowout’.

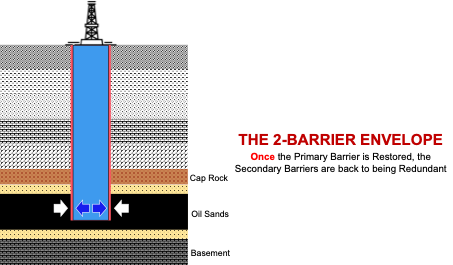

An effective well barrier management model requires the establishment of a 2-barrier envelope during all well operations and includes procedures and policies for the testing and monitoring of well barriers and for the re-establishment of failed barriers.

The figures below illustrates a basic 2-barrier envelope principle. Although simplified and illustrated for ‘Drilling’, the concept is applicable and required for all well operations.

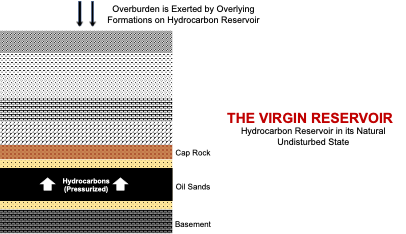

Figure 1 shows a Virgin Reservoir

in its Natural State. Overburden from the overlying formations pressurizes the hydrocarbons trapped in the pore spaces of the reservoir rock. The cap rock that overlays the reservoir rock acts as a natural seal and holds the accumulation in place.

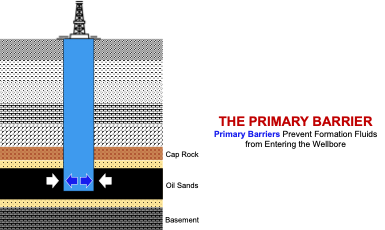

Figure 2: When a well is drilled into the hydrocarbon bearing reservoir, the pressurized hydrocarbons tend to flow into the wellbore (a natural tendency to flow from a higher to a lower pressure state). The drilling fluid (drilling mud) provides an overbalance in the wellbore and prevents the flow of hydrocarbons into the well. Here, the overbalance provided by the drilling fluid makes the primary

well barrier.

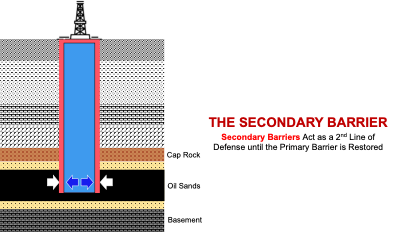

Figure 3: When the primary barrier fails – The overbalance is lost and hydrocarbons have entered the wellbore, a 2nd line of defense is required that prevents the hydrocarbons from being released into a weaker zone or into the environment. The secondary well barriers (Casings, Cement, Wellhead Seals, BOPE, etc) act as the 2nd line of defense and maintain control of the well until the primary barrier is re-established. Drilling resumes only after the primary well barrier is re-established.

Figure 4: After the primary barrier has been re-established, the secondary barriers return to their redundant state until required again. Well operations must remain suspended until the primary barrier is re-established and not conducted under only the secondary barrier envelope.

Vignesh is a Petroleum Engineer with more than 10 years of experience in Well Integrity and Well Engineering. He is the founder of iDrilling Technologies and is actively consulting Oil Operators on Well Integrity and Risk Aversion solutions.

All author postsWhen a well is constructed section by section, during any...

‘Well Integrity’ is essentially a crucial component in...